Electronics and optics

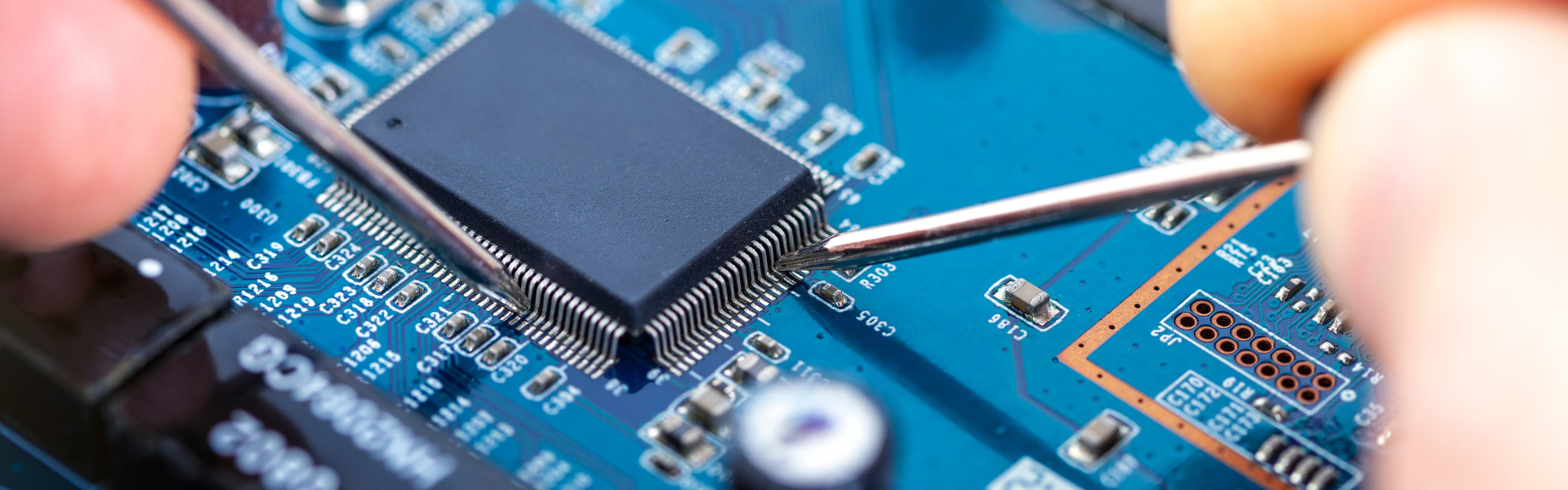

We guarantee the reliability of processes in the electronics and optics industry

Filtration for the electronics and optics industry

Filtration solutions for HVAC systems for critical areas highly sensitive to particulate pollution and energy savings.

Critical Zones

Air filters are essential for reliably and safely manufacturing electronic and optical devices. In this type of industry the processes are especially delicate and can be easily affected by all kinds of particles. Therefore, they require a totally clean and controlled environment governed by strict regulations and requirements to guarantee the safety of processes and products.

The air conditioning and management of the ventilation of these facilities implies having controlled unwanted particles in the air and reduce or minimise adverse effects that may affect people, materials and the environment, by: the treatment, transport, filtration and impulsion of air: ensuring a high level of cleanliness and quality to protect products, processes, people and the environment from pollutants.

Areas to be adapted to reduce and avoid particulate pollution:

- Laboratories

- Clean rooms

- Production areas

- Data Centers

- Air handling units

Applications

Our range of products for the electronics and optics industry have been developed for different applications in:

Why air filtration systems for the electronics and optics industry?

Installations in the electronics and optics industry require special air conditioning and ventilation systems. Without proper control and treatment it can become a risk for products and processes.

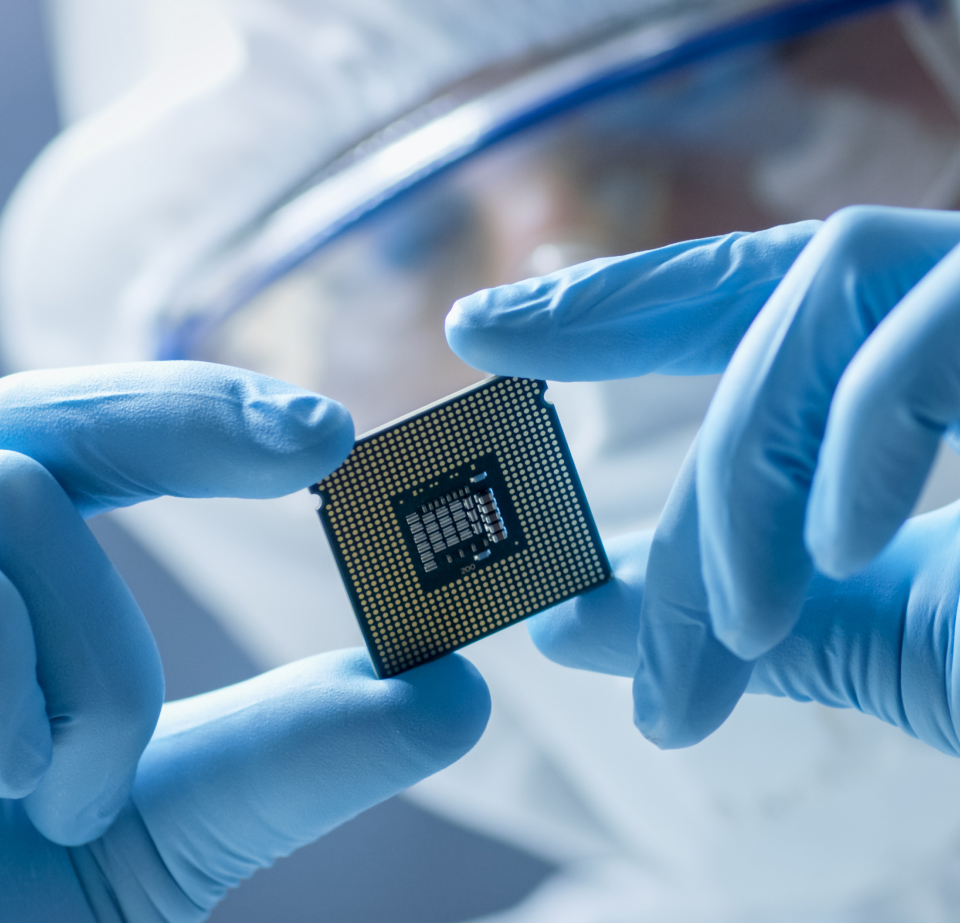

A good filtration system will save us from corrosion problems and also ensure that our product is in good condition and we do not lose production. In addition, we will protect our human team from possible harmful gases and particles released by the devices.

It is important to conduct a thorough analysis of air filtration needs and consider factors such as ambient air quality, sensitivity of electronic components and applicable regulations before selecting and implementing a suitable filtration system.

Sources of contamination

In these industries, the main sources of particulate air pollution can vary depending on the installations, equipment, people, raw materials, etc.

Particular care must be taken with ventilation ducts, as the air may not be properly filtered and pollutants may be allowed to circulate freely.

The most frequent pollutants in the sector that pose a risk are:

- Outdoor particles such as pollen, dust, hair….

- Chemical gases given off by electronic devices

- Sulphur dioxide, hydrogen sulphide, silicon dioxide, among others.

The function of a general ventilation system is to provide air flows, with the ideal temperature, humidity and air quality in the different areas providing clean air to the equipment to remove airborne contaminants from the most critical areas.

Filter and air conditioning in the electronics and optics industry

Venfilter filters and filter media are certified and meet the highest standards for data centers, clean rooms, production and manufacturing areas microelectronics components and lenses.

The air conditioning systems of the facilities of these industries must comply with the strictest requirements in terms of protection and safety. They must ensure the absence of particulate contaminants, especially in those most critical areas. Only systems with highly efficient filters can provide these types of controls.

Get peace of mind in all your sensitive processes. Venfilter offers filtration solutions for safe and reliable HVAC systems. Talk to our experts.