Life Sciences

We guarantee the reliability of processes in the Pharmaceutical, Veterinary, Cosmetic and Biotechnology industries

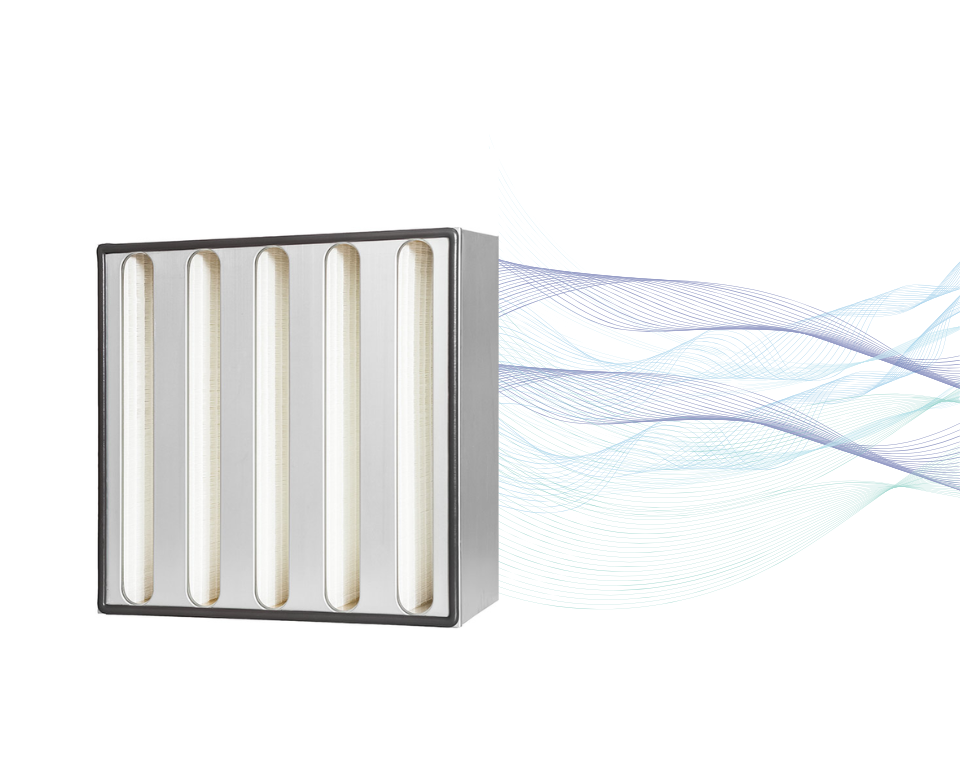

Venfilter Safe Life. Filtration for the Pharmaceutical, Veterinary, Cosmetic and Biotechnology Industries

Filtration solutions for hygienic air conditioning systems for critical areas highly sensitive to microbial contamination.

In Venfilter we design and manufacture air filters to achieve the highest quality indexes and energy savings in the same product.

Research Centers, as well as the manufacture of medicines, medical devices, food supplements or cosmetics are governed by the highest quality and safety criteria for both the product and people.

A controlled environment is essential to ensure the integrity of the drug or device and to ensure the repeatability and reproducibility of the production process once validated.

Likewise,

Likewise, the safety of personnel who may be exposed to contaminants is also paramount. It is imperative that researchers and laboratory employees are protected from contamination. It is also essential to prevent contaminating micro-organisms from escaping from these controlled environments.

Critical areas

Air filters are essential for the reliable and safe production of pharmaceuticals, medical devices, cosmetics and biopharmaceuticals. Processes in these industries are particularly sensitive and can be easily affected. They require a totally clean and controlled environment with strict regulations and requirements to ensure the safety of processes and products.

The air conditioning and management of the ventilation of these facilities implies having controlled unwanted particles in the air and reduce or minimise adverse effects that may affect people, materials and the environment, by: the treatment, transport, filtration and impulsion of air: ensuring a high level of cleanliness and quality to protect products, processes, people and the environment from pollutants

Areas to be adapted to reduce and avoid microbiological contamination:

- Laboratories

- Aseptic processing clean rooms

- Production and packaging areas

- Air handling units

Applications

Our Venfilter Safe Life product range has been developed for different applications in:

Why air filtration systems for the pharmaceutical, cosmetic and biotechnology industries?

The facilities of the pharmaceutical, veterinary, cosmetic and biotechnological industries require special air conditioning and ventilation systems. Without proper control and treatment it can become a risk to products, processes, people and the environment.

The microscopic dimension of the sources of pollution, due to their size, hinder the problem, because the air contains different microorganisms:

- Pollen 10 microns

- Viruses between 1/100 and 1/1000 micron

- Bacteria between 0.2 and 10 microns

- Fungal Spores varies between 1 and 10 microns

A cubic meter of outside air can contain between 200 and 1500 bacteria, which in a ventilation system with an air flow of 10,000 m3 / h. We can introduce between 2 to 10 million bacteria per hour in a production plant. Inefficient air filtration it cannot guarantee the reliability of the processes.

Sources of contamination

In these industries, the main sources of microbiological air pollution can vary depending on the facilities, equipment, people, raw materials…

It is necessary to be especially rigorous with the ventilation ducts, since the air may not be filtered correctly and allow contaminants such as dust, pollen and bacteria in suspension to circulate freely. Also, the mold and spores present in the humidity of these same ducts can become a problem beyond air quality.

The function of a general ventilation system is to provide the air flows, with the ideal temperature, humidity and air quality in the different areas providing clean air to the equipment to eliminate from the most critical areas, the pollutants transported by the air.

Filter and air conditioning in the pharmaceutical, cosmetic, veterinary and biotechnology industries

Venfilter filters and filter media are certified and comply with the most demanding regulations for sterile room installations, laboratories and production and packaging areas for the pharmaceutical, cosmetic, veterinary and biotechnological industries.

The air conditioning systems of the facilities of these industries must comply with the strictest requirements in terms of protection and safety. They must guarantee the absence of microscopic contaminants and microorganisms, especially in those most critical areas (laboratories, clean rooms, production and packaging areas, etc.) and optimal comfort conditions. Only systems with highly efficient filters can provide these types of controls.

Get peace of mind in all your sensitive processes. Venfilter offers filtration solutions for safe and reliable HVAC systems. Talk to our experts.