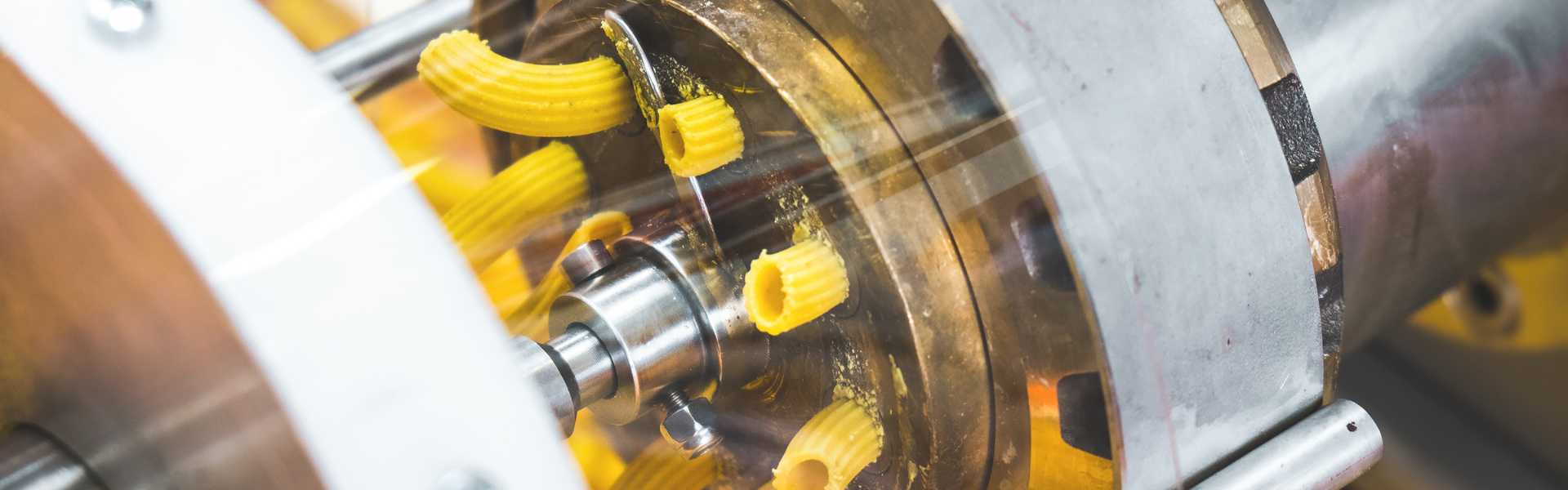

Food secure products for the food industry

We offer a wide range of products certified as suitable for use within the production and food handling environment.

EC 1935:2004 Suitability for food contact Regulation 1935/2004 introduces the principle of inertness (Article 3): materials and articles must be manufactured in accordance with good manufacturing practice so that, under normal or foreseeable conditions of use, they do not transfer to the constituent foodstuffs in an amount that may:

- Endanger human health.

- Cause an unacceptable change in the composition of the products or an alteration of their organoleptic characteristics.

Critical Zones

Design in a clean food production plant will be difficult. For certain production areas, they will need clean zones such as those used in the pharmaceutical industry to remove contamination due to microscopic contaminants and microorganisms. This technology is used to increase air cleanliness in critical areas or in clean room type facilities for sensitive processes, where working methods and the design of processing equipment are of greater importance and need to be planned.

When the air in a process is cleaned with absolute filters, the airborne microorganisms are not transferred to the products exposed to the filter air.

Areas to be adapted to reduce and avoid microbiological contamination:

- Warehousing and packaging areas

- Foodstuff reception

- In the prefiltration to prevent the growth of colonies due to accumulated organic matter and the development of microorganisms.

- Processing Areas

- Areas for Cutting, deboning, shredding and preparation of the end product [clean rooms].

Applications

Click on each application in our Venfilter Food Secure range and find out how we can help you improve your processes.

Why air filtration systems for the food sector?

In the production and processing of food from the centers, air can become a risk in the feed, due to microbiological contamination.

The microscopic dimension of the sources of pollution, due to their size, hinder the problem, because the air contains different microorganisms:

- Pollen 10 microns

- Viruses between 1/100 and 1/1000 micron

- Bacteria between 0.2 and 10 microns

- Fungal Spores varies between 1 and 10 microns

One cubic metre of outdoor air can contain between 200 and 1500 bacteria. In a ventilation system with an airflow of 10,000 m3/h we can introduce between 2 to 10 million bacteria per hour into a crowded space. This can lead to air pollution and affect people’s health and comfort.

Sources of contamination

In industrial food production, the greatest risks of microbiological contamination in the handling of raw or processed food, its sources of contamination may vary, coming from unhygienic equipment, facilities, air, ventilation, personnel, raw materials.

The function of a general ventilation system is to provide air flows, with the ideal temperature, humidity and air quality in the various areas. Providing clean air to the equipment to remove airborne contaminants from critical areas.

- Microbiological contamination, mainly bacteria, yeasts and moulds, which can contaminate systems through compressed air.

- Environmental factors, air entering from outside can contain micro-organisms, water, oil, rust and pipe scale.

- Climatic conditions, warm and humid environments are ideal for microbial growth. Excessive oil and water in a compressor system creates a breeding ground for microorganisms.

- Biofilm contamination, lack of proper monitoring and maintenance in the piping system can result in the production of biofilm. This biofilm contaminates the compressed air as it flows through the system, and can be very tough and difficult to clean.

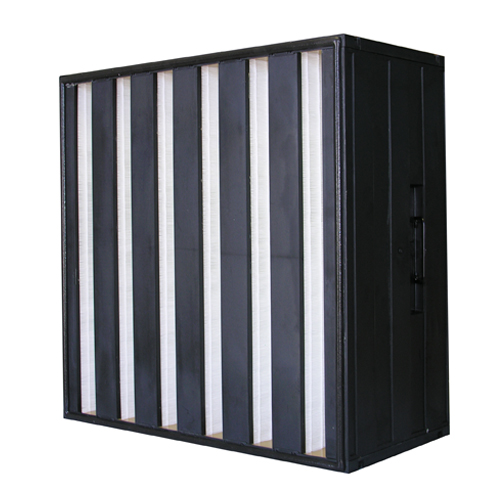

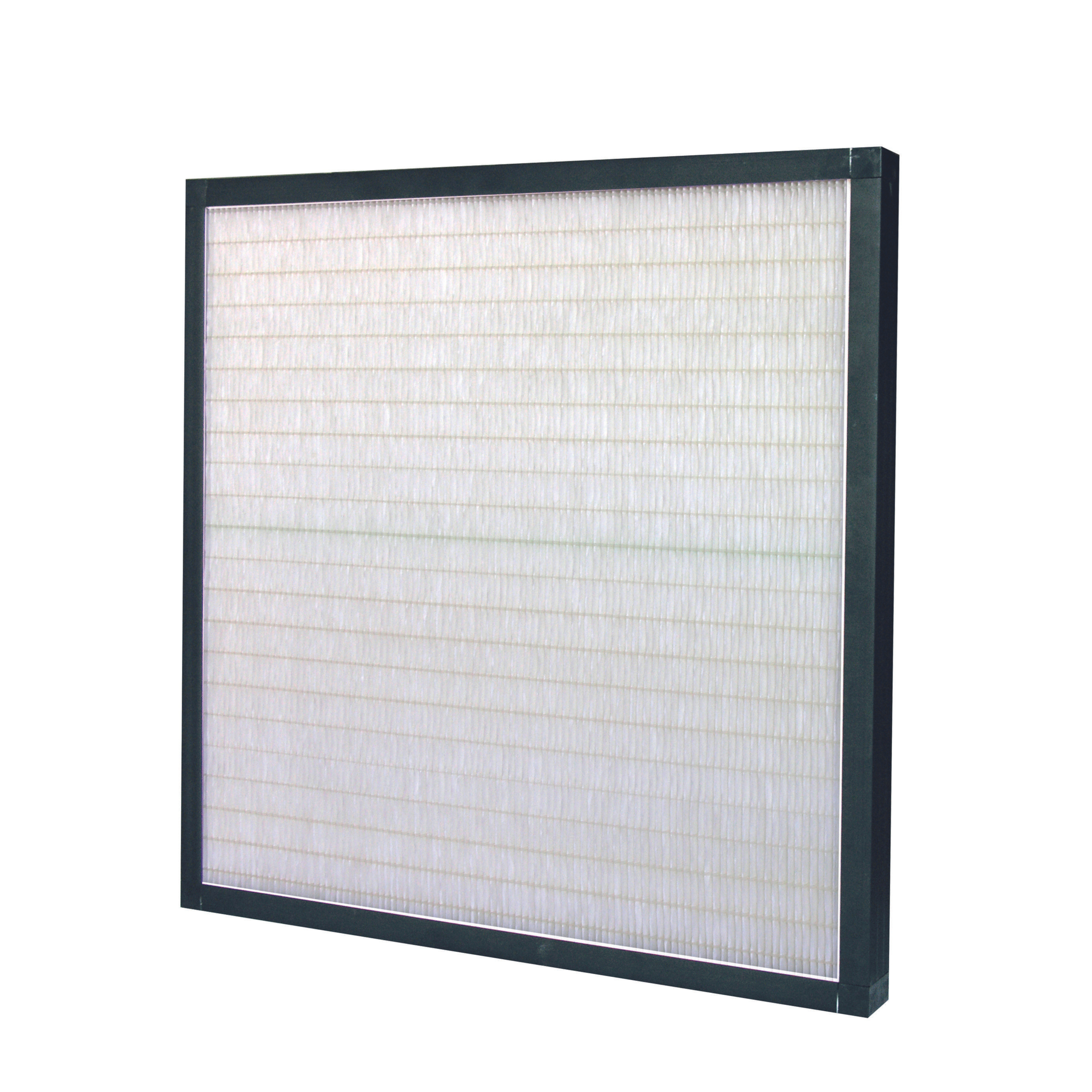

Filter and air conditioning in the food industry

Venfilter filters for production plants, certify that their filter media are suitable with respect to the EC 1935/2004 standard, this regulation establishes that materials that are in contact with the production process and food do not transmit any component to food, which may be harmful to human health or the alteration of the product.

The food processing industry is sensitive to air filtration to prevent microbial loading. Temperature and humidity need to be controlled. Only reliable systems with highly efficient filters can provide these types of controls. To prevent the air conditioning system from becoming colonies of microbes, temperature and humidity must be controlled and accumulated organic matter removed, as clogged exchangers provide good support for the development of microorganisms.

Venfilter offers filtration solutions for hygienic HVAC systems that are sensitive to microbial contamination and corrosion Talk to our experts!

Our Food Secure product range:

Suitable for EC1935/2004 for food contact