Astroven (Galvanized)

The HEPA absolute filters are used for filtration of inlet, outlet and recirculation air in ventilation systems such as: Air Inlet (Clean Rooms, Operating Theatres, Laboratories, etc.), Industrial Processes (Microelectronics, Food Industry, Optics, Pharmaceutical Industry, Fine Chemistry, etc.) and Treatment of Dangerous Substances (Asbestos, Metal dust, Bacteria, Viruses, Radioactive Particles).

Technical features

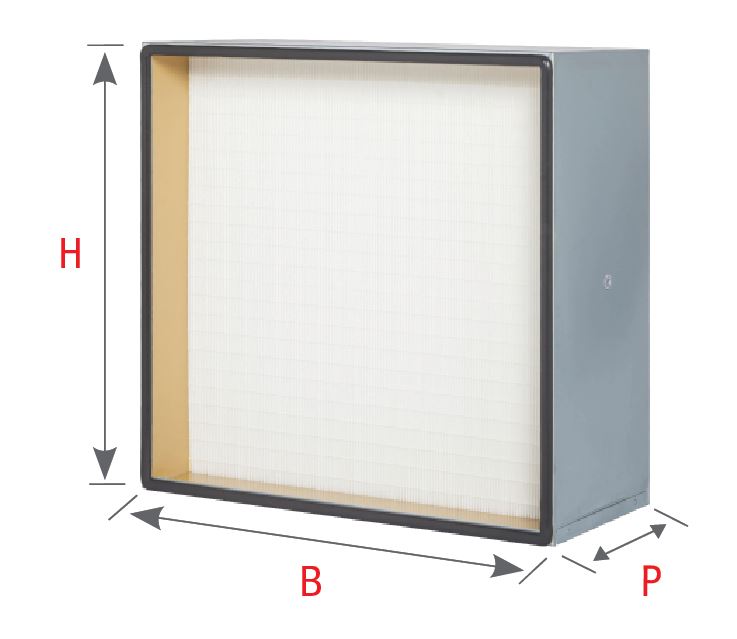

Type: Compact Very High Efficiency Absolute Filter.

Frame: Galvanized Steel.

Filtering Element: Glass microfiber paper.

Separators: Thermoplastic glue beads.

Sealant: Polyurethane.

Joint: Bicomponent polyurethane liquid system. (Semi-circular expanded polyurethane)

MPPS Efficiency: 99.95% and 99.995%.

EN 1822 Class: H13 and H14.

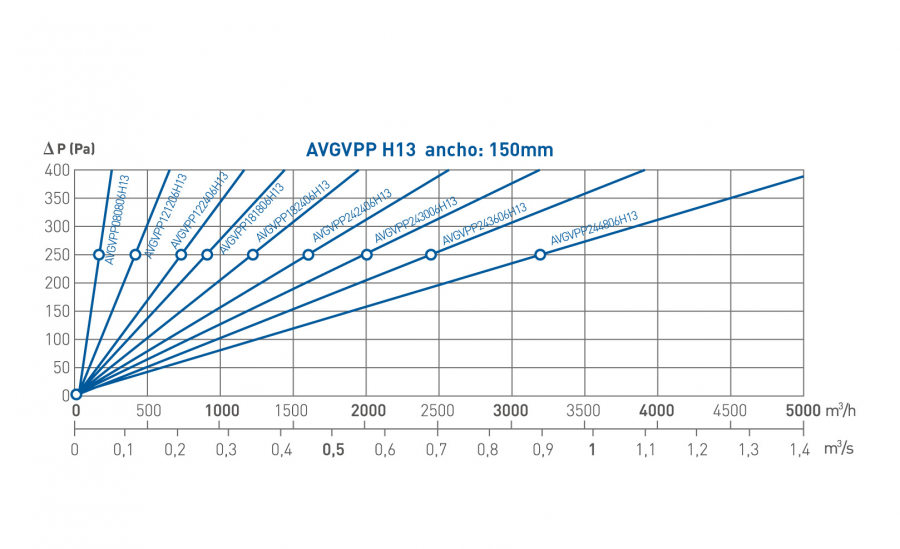

Recommended Final Pressure Loss: 600 Pa.

Temperature: 80ºC in continuous service.

Advantages

– TheV-shaped pleating method guarantees an optimum geometry of the pleats and a uniform distance between them,

resulting in a lower pressure loss with a higher airflow.

– V-shaped pleating technology allows us to remove the aluminium separators and thereby eliminate the risk of

leaks due to the perforations of the aluminium separators.

– The filter is light and easy to eliminate thanks to the new manufacturing technology.

– The total use of the filtering area, in addition to the uniform dust deposition achieved through the new pleat shape

technology, leads to longer duration.

– Due to the increased filtering area, the speed of the air through the filter and the resistance to flow decrease, resulting in energy saving.

– Thanks to the uniform shape of the pleats the airflow does not generate turbulences.

– The Microven filters provide more protection and reliability as a result of the larger filtration area achieved by the new pleating

shape technology. Also filtration efficiency is improved and the cost-efficiency ratio is excellent.

– The filter media is self-extinguishing glass microfiber paper (class F-1) and resistant to humidity up to 100% relative humidity.